What actually happens to our waste after it leaves our University?

Did you know your sandwich packaging can be used to generate energy?

Non-recyclable waste is processed by Enva and sold to other companies to generate heat and power in buildings. But how exactly does Enva do this?

The first stage is to sort through the materials collected in the non-recyclable waste, separating cardboard, timber, and electrical waste. Enva can be even more efficient with their energy recovery for these products.

This waste is then shredded. It is placed through a trommel, a machine designed to separate those materials by size whilst removing fines. Fines are waste that has been reduced to a very fine, soil or sand consistency. These are too small for any energy recovery.

Once through the trommel, metals will be removed by an over-band magnet, these metals will be used for further and more sustainable resource recovery.

With materials sorted and ready to go, bailing and wrapping commences and the finished bails of fuel are transported across to recovery facilities in the U.K and in Europe This fuel is then used to heat homes and small businesses.

Have you ever wondered what happens to your recyclable waste?

Enva, who have been working as a sustainable waste management provider in Nottingham for over a decade, have collaborated with us to explain to us exactly what happens.

Our University teams take your waste to the closest outdoor bin compound. Enva then collects our recycling early in the morning and transports it to one of their local sites in Nottingham and Leicester.

There your waste is placed through a “hopper” feed, this equipment is designed to aid the sorting of materials and feed them into the first manual segregation step, pickers.

Enva’s manual pickers begin the segregation process by sorting recyclable materials and removing anything that would be dangerous to the facility such as batteries.

Waste is placed through a “Ballistic separator” to separate 2D and 3D material, in theory separating metals and plastics from paper and card as well as removing glass from the process entirely. Further Manual Picking takes place on both 2D and 3D waste streams to ensure complete segregation.

From there, the metals are removed with an over band and eddy current magnet, and all recyclable waste types are fed into an automatic bailer. This machine cubes the waste for transportation to a recycling materials facility such as a paper mill where they can treat the waste to be sent back out onto the market.

Loughborough University Visit to Enva:

On 8th February 2023, I took a group of student Sustainability Ambassadors from Loughborough University to Enva on Colwick Industrial Estate in Nottingham for a site tour.

I asked the students to write a few sentences to reflect on their experience…

Gavin Bath: “I found the Enva site tour really eye-opening and informative, when we throw away waste it’s all too easy to think that it is transported to a different galaxy and that it just disappears! The trip to Enva really showed me the extent of waste that is produced by just one area and how effective recycling can be. We need to make sure that we keep on recycling in order to do our bit to make the world greener.”

Gayatri Achari: “I got the chance to see how the general waste from cities are managed at Enva. The segregation process for each type of waste and the effort needed was shown. I can’t emphasize enough on the size of the mountains of waste collected at this site. It was eye-opening to witness the energy and human effort required for this segregation and is time consuming. With this tour, I have realised we could start with segregating the type of waste we generate as bare minimum so that the energy and time for waste management can also be efficient.”

Derek Amoakwao: The visit to Enva was very insightful, in a sense that we got a clearer picture of where exactly our waste ended up and pretty much re emphasized the need to manage /waste properly. It is interesting to note that Refuse derived fuel (RDF) which is produced from the bio degradable materials such as plastics is used to produce energy for communal/ council heating systems, construction of kilns and at recovery facilities in production of energy.

Jamie Wilks: Visiting the Enva recycling centre was an interesting experience for the following reasons. Firstly, to see where all the University waste is transported to and to quantify how much waste the university produces. Also, learning that 97% of Loughborough University’s waste is recycled in some form. Additionally, the process of how the waste is separated between 2D and 3D waste by using magnets and an air gun. Finally, I found it interesting that large percentages of the waste is shipped to Sweden or France to be used as fuel. This is because the UK does not have the capacity to burn this form of waste for energy at this time.

So, what can you do?

Take a look at our A-Z recycling list to check how to correctly dispose of any item!

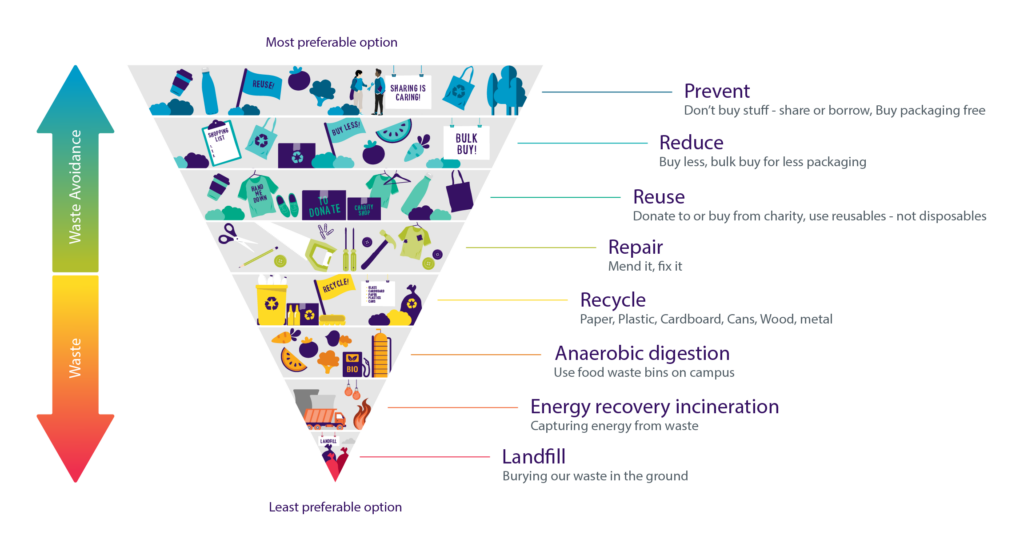

Make sure to familiarise yourself with where the British Heart Foundation banks are on campus. You can donate your items there for re-use, which comes above recycle within the waste hierarchy (as shown below).

As you can see on the waste hierarchy, prevention is the best and most preferable option! One easy way that you can prevent waste is to take part in our Ditch the Disposables campaign, and get yourself a reusable coffee cup to use on campus. The ‘Loughborough Cups’ are now back in stock with a new design throughout our campus retail stores, and they get you a 25p discount when you use them too!

This article is in support of the United Nations Sustainable Development Goal 12: Responsible Consumption and Production. To read more click here.

Sustainably Speaking

Loughborough University Sustainability Blog