Printing Green

Guest blog by Helen Clarke, on behalf of Loughborough University’s Print, Post and Logistic Services Team.

The print and paper industries have a major issue with misconceptions about their impact on the environment. Many large companies have been tackled for ‘green washing’, after encouraging their customers to switch to electronic bills and statements with the incentive to switch based on unfounded environmental claims, such as “Save the planet – go paperless”.

According to the Advertising Standards Authority, marketing must be clear, truthful, accurate and not misleading. Environmental claims made against print and paper go against that.

‘Paper is a uniquely renewable and sustainable product’ (Two Sides – Start telling the sustainable story of print, paper and paper packaging) and here in Print, Post and Logistic Services, we are seeking to ensure that that message gets through good and clear.

2022 saw us take a leap to support this, and the University’s Journey to Net Zero.

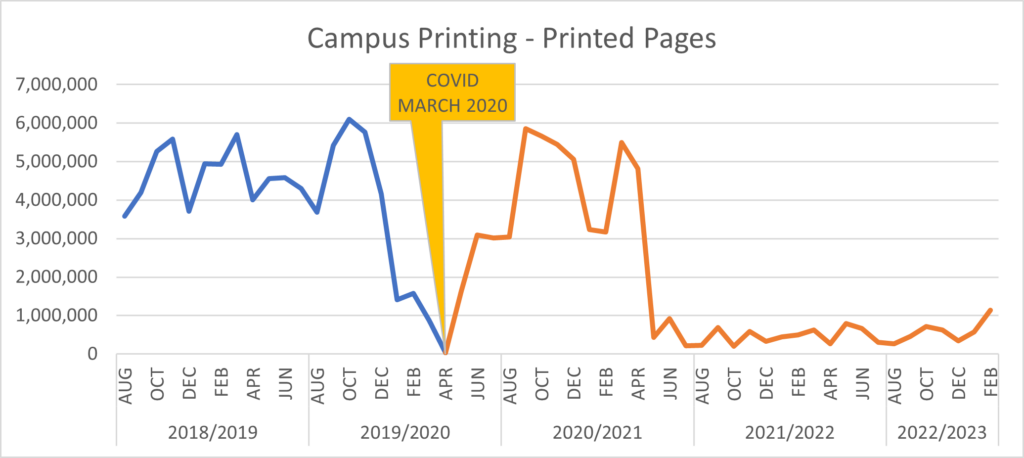

We manage the 200+ Campus Printers across campus for shared use by staff, students, and campus partners. Following the Covid-19 pandemic we have seen a dramatic drop in print output on these devices.

In 2022, considering that shift in activity, we upgraded the entire Campus Printing fleet. We’ve removed 50 low usage devices, and moved others to high footfall areas to ensure effective utilisation.

These new printers all power down when not in use, making them more energy efficient than the previous models and standalone printers.

The new fleet is fully supported by Ricoh who further support our ambitions through their ‘Zero Waste to Landfill’ methodology in accordance with WEEE regulation ‘free-of-charge’ consumable disposal service to the University for waste/used toner and their “Engineer-Parts-Return-System”. Some of the components are potentially in “as-new” condition and are reused. Parts that cannot be reused are segregated/ground down, ensuring that near-virgin grade of materials can be used again.

The toner used in our Campus Printers is made from plant-based renewable materials. To lessen the environmental impact of producing toner, Ricoh has been developing a biomass1 toner, for which they adopted a plant-based resin. This biomass toner requires less petroleum than conventional toner, and contributes to the prevention of petroleum depletion. Being carbon neutral, biomass toner works to reduce the net amount of CO2 emitted from the combustion of used toner.

As part of the MFD upgrade, we moved from Safecom to the PaperCut software package. Their portal increases our ability to monitor printing activity, paper usage and our environmental impact.

Did you know… Schools and professional services can monitor their own printing activity by completing this form to request automated reports each month.

Furthermore, the above standard paper for Campus Printers is Steinbeis No.1. 100 % recycled and processed without any environmental harmful bleaching agents (chlorine, chlorine-dioxide, or other halogenated bleaching agents), the paper is certified to Blue Angel and EU-Ecolabel standard. This paper can also be recycled after use. Whiter papers can be purchased via the Online Shop where needed.

Our next big project is to upgrade our in-house production equipment with the introduction of lower energy usage cut sheet devices, enhanced inline finishing, and Loughborough’s first flatbed print machine. This is a significant upgrade to our capability and will enable us to print onto a wide range of sustainable materials for internal and external use, as well as re-use materials we have already procured such as signage. Please follow us on Twitter (@LboroPrintPost) for updates on this project .

This article is in support of UN Sustainable Development Goal 12 ‘Responsible consumption and production’. To find out more, click here.

Sustainably Speaking

Loughborough University Sustainability Blog